15 Aug What is electrical discharge machining?

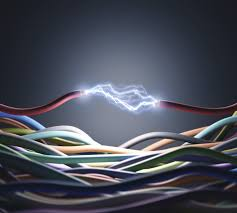

Electrical discharge machining (EDM) is a non-traditional machining process that utilises electrical sparks. The material used must be conductive.

The sparks are created from a path of electrical discharge which connects an electrode and the workpiece. The sparks can reach temperatures of up to 12,000 degrees Celsius.

These sparks vaporise and melt the material around the shape. A dielectric fluid is used to remove debris.

Types of EDM

There are three common types of EDM: die-sinking EDM, wire EDM, and hole-drilling EDM.

Die-sinking EDM

Die-sinking EDM is considered the best option when creating parts that have complex cavities or sharp internal corners. It uses graphite or copper electrodes, an electric spark and a dielectric fluid.

An electrode is generated in the reverse shape of the desired cavity, forming the ‘die’. The die is then lowered towards the workpiece causing the sparks to vaporise and melt the material. The desired shape then emerges.

Wire EDM

Wire EDM is often used to produce extrusion dies. It cuts using the same mechanism as seen in die-sinking but the die is replaced by a thin electrically-charged wire. Wire EDM can produce high-precision cuts.

Hole-drilling EDM

As the name implies, this method is widely used to machine holes. It can accurately machine extremely small and/or deep holes that will not need deburring. The cutting in this method is via a pulsing cylindrical electrode.

Advantages of EDM

There are several advantages to using EDM over other methods. It offers greater design freedom and high-level precision. It does not create a burr, there is no distortion and it creates a uniformly smooth surface. It is also able to machine through almost any material (no matter how hard), including the likes of Tungsten and Inconel.

Electric Tapping Machines

Electric tapping machines are a popular option for adding internal threads. There are a number of specialists in this sphere who have useful online resources, such as the Examples seen here:https://www.cotswold-machinery-sales.co.uk/roscamat-tapping-machines/electric-tapping-machines/roscamat-tiger-electric-tapping-machine

EDM Applications

Some key applications for EDM include micro-hole drilling, creating injection moulding tools, cutting extrusions and engraving on hard materials.